Monday, December 14, 2015

Tuesday, December 8, 2015

Glasses 3D design on Tinkercad

This is my 3D design of glasses.

The frame is thin, so it looks elegant and nice. The lenses shape can be different, but I prefer the round one. There can be colored lenses and customer can choose any color for the frame. Some people would prefer the transparent lenses, because colored once may distort the original colors, like some sunglasses do.

Comparing to my drawing, 3D design looks better and more accurate.

Saturday, November 21, 2015

Design

My design is glasses in which lenses would be suitable for several sight powers, so you won't need to change lenses for a while, even if you sight power changes. One pair of glasses can be suitable only for 30 different sight powers. Otherwise the lens would be too thick.

Here are two examples of how can glasses look.

So, glasses can be any shape, color and material. The price will depend on design the glasses.

I've also completed a research on different types of lenses.

· Polycarbonate lenses. These eyeglass lenses are impact-resistant and are a good

choice for people who regularly participate in sports, work in an environment

in which their eyeglasses may be easily scratched or broken, and for children

who may easily drop and scratch their eyeglasses. Polycarbonate lenses also

provide ultraviolet protection.

·

Trivex lenses. These lenses are made from a newer plastic with similar

characteristics of polycarbonate lenses. They are lightweight, thin, and

impact-resistant and may result in bettervision correction

than the polycarbonate lenses for some people.

·

High index plastic lenses. Designed for people who require strongprescriptions, these

eyeglass lenses are lighter and thinner than the standard, thick "coke

bottle" lenses that may otherwise be needed.

·

Aspheric lenses. These eyeglass lenses are unlike typical lenses, which are

spherical in shape. Aspheric lenses are made up of differing degrees of

curvature over its surface, which allows the lens to be thinner and flatter

than other lenses. This also creates an eyeglass lens with a much larger usable

portion than the standard lens.

·

Photochromic lenses. Made from either glass or plastic, these eyeglasses change

from clear to tinted when exposed to sunlight. This eliminates the need for

prescription sunglasses.

These eyeglass lenses may not darken in a car because the windshield could

block the ultraviolet rays from the sun.

·

Polarized sunglasses. Light reflected from water or a flat surface can cause

unwanted glare. Polarized lenses reduce glare and are useful for sports and

driving. These lenses may cause the liquid crystal displays on the dashboard of

cars to appear invisible.

References:

n/a. (2015). Eyeglasses and Your Eyes. Available: http://www.webmd.com/eye-health/eyeglasses-eyes. Last accessed 21 Nov 2015.

Friday, November 13, 2015

Child Friendly Syringe - Rabbit

My task was to create a child friendly syringe. I thought of a rabbit because they are fury and cute. When children are afraid of needles, nurses could give them a toy, so children would be distracted from a needle. I made a syringe like a carrot,so the child would think it's also a toy.

For head and legs I used spheres and half spheres shapes. For nose I used pyramid shape and for mouth - round roof shape. I found bunny ears shapes in extras. And terrain in generated shapes.

For a carrot I used cone and half sphere shapes. Greens are originally a tree shape in generated shapes. For needle I used a sphere.

Wednesday, October 28, 2015

Project - 3D Modelling and Design

Questionnaire about my project

Questions

|

Answers

|

Do you think it will work for all the people?

|

4/10 people answered yes.

6/10 people answered no.

|

Is it going to be comfortable not to change lenses in the glasses?

|

10/10 people answered yes.

|

Would you prefer colorful or transparent lenses?

|

7/10 people have chosen transparent lenses.

3/10 people have chosen transparent lenses.

|

Would you buy those glasses?

|

8/10 people answered yes.

2/10 people answered no.

|

Tuesday, October 27, 2015

Project - 3D Modelling and Design

Inquiry and

Analysis

I am a

student of Technology. As part of the MYP design term 1, we are using the

software Tinkercad that helps design 3D objects. Computer Aided Design has

involved as a unique way of creating 2D and 3D Objects. It is used to create

precision on drawings or technical illustrations.

There is a lot to do on Tinkercad and I am looking forward to

do some more awesome designs!

I will create a project to improve community and help people. I want to create special glasses, that would be suitable for all people. People have different sight power, but the lenses would be universal. You won’t need to

change lenses in them even if your sight power will change.

Inquiry and

Analysis

Statement

of inquiry: Digital

design and Printing as a form of communication and output has evolved through

time and space to influence audience's perspective.

I am a

student of Technology. As part of the MYP design term 1, we are using the

software Tinkercad that helps design 3D objects. Computer Aided Design has

involved as a unique way of creating 2D and 3D Objects. It is used to create

precision on drawings or technical illustrations.

Tinkercad is an easy, browser-based 3D design and modeling

tool for all. Tinkercad allows users to imagine anything and then design

it in minutes. Tinkercad

is a simple, online 3D design and 3d printing tool for the masses. Whether you

are a designer, hobbyist, teacher, or student, you can use Tinkercad to make

toys, prototypes, home decor, Minecraft models, jewelry – the list is truly

endless!

You

dream it, you can make it. My goal is to

become a proficient Tinkerer!

Tinkercad was founded by Kai Backman and Mikko Mononen in

2011, bringing the first browser-based 3D design platform to the masses.

You can show all of your creativity, using Tinkercad. After

completing basic lessons and simple designs that are guiding you step by step,

you can easily create whatever comes to your mind. Also, you can print your

designs in 3D format! You can see others’ creations and others can see your

work.

Sometimes you need to be patient about your projects to make

them really original and interesting.

There is a lot to do on Tinkercad and I am looking forward to

do some more awesome designs!

I will create a project to improve community and help people. I want to create special glasses, that would be suitable for all people. People have different sight power, but the lenses would be universal. You won’t need to change lenses in them even if your sight power will change.

I will create a project to improve community and help people. I want to create special glasses, that would be suitable for all people. People have different sight power, but the lenses would be universal. You won’t need to change lenses in them even if your sight power will change.

Saturday, October 24, 2015

Monday, October 12, 2015

Design 3

I did Design 3 - a house.

Step 1.

I put a box shape on the workplane and scaled it to the size 49×36×36. Then made it purple color.

Step 2.

I put another box shape and scaled it to the size 1.50×0.75×19. Made it yellow color and put it in front of the purple box. This is a door.

Step 3.

I put a workplane on top of the purple box and put a roof shape. Then scaled it to the size 54×39×10.

Step 4.

I dragged a box shape on the workplane and scaled it to the size 11×12×48. Then I dragged it inside the house to the corner, so it will look like a chimney. And later made it purple color.

Step 5.

I put a workplane on top of the chimney. Then I was putting 5 sphere shapes size of 10×10×10 on top of each other, so it would like smoke coming out of the chimney. After, I grouped the spheres and made them light grey color.

So, this is what I had after I finished the steps above:

Step 1.

I put a box shape on the workplane and scaled it to the size 49×36×36. Then made it purple color.

Step 2.

I put another box shape and scaled it to the size 1.50×0.75×19. Made it yellow color and put it in front of the purple box. This is a door.

Step 3.

I put a workplane on top of the purple box and put a roof shape. Then scaled it to the size 54×39×10.

Step 4.

I dragged a box shape on the workplane and scaled it to the size 11×12×48. Then I dragged it inside the house to the corner, so it will look like a chimney. And later made it purple color.

Step 5.

I put a workplane on top of the chimney. Then I was putting 5 sphere shapes size of 10×10×10 on top of each other, so it would like smoke coming out of the chimney. After, I grouped the spheres and made them light grey color.

So, this is what I had after I finished the steps above:

Tuesday, October 6, 2015

Tinkercad

Tinkercad is an online 3D design and 3D printing tool for the

masses. Whether you're a designer, hobbyist, teacher, or kid, you can use Tinkercad to make toys, prototypes, home decor, jewelry – the list is endless! There are over 4 million designs created with hundreds of new designs being added daily.

I joined Tinkercad and done basic lessons.

First was "Camera controls". This was pretty easy. I can use arrows on the left upper corner or do it easier with a mouse holding right button down. To zoom I can use either buttons on the screen or scroll wheel.

Second lesson was "Learning the moves". It also wasn't hard to complete. To move objects I just need to press left button on the mouse and move it.

Third was "Scale, Copy & Paste". Scaling takes a bit of time, but copying and pasting is the easiest. First, I dragged two cylinders. Then I scaled the second one to height of 15mm by dragging white dot on top of it down. Then i needed to copy the cylinder and scale it to height of 10mm. To copy objects I can either press Ctrl+C and Ctrl+V or press Alt while moving object.

masses. Whether you're a designer, hobbyist, teacher, or kid, you can use Tinkercad to make toys, prototypes, home decor, jewelry – the list is endless! There are over 4 million designs created with hundreds of new designs being added daily.

I joined Tinkercad and done basic lessons.

First was "Camera controls". This was pretty easy. I can use arrows on the left upper corner or do it easier with a mouse holding right button down. To zoom I can use either buttons on the screen or scroll wheel.

Fourth lesson was "Creating holes". To create a hole I just to choose the hole feature from the inspector in right upper corner. Then I need to group object with a hole figure and the hole is created.

Fifth lesson was "Key ring, letters!" I dragged letters of my name to the base and changed their color. After that, I resized the base to fit the length of the text by moving black dot on right edge of the base.Then I removed remaining letters off the workplane. And the last step was to group everything and make it multicolor. Done!

The last lesson was "Die on the workplane" First, I dragged workplane on the side on the die. Then I dragged number 5 on the workplane and made it 1mm height. Later, I did the same with number 6 on top of the die. To reset the original view I needed to drag workplane to empty spot. Then I grouped all objects. Finished!

Monday, September 28, 2015

3D Printing

3D printing

3D printing is an additive technology in which objects are built up in a great many very thin layers. The first commercial 3D printer was based on a technique called stereolithography. This was invented by Charles Hull in 1984.

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the entire object is created.

Many different materials can be used for 3D printing, such as ABSplastic, PLA, polyamide (nylon), glass filled polyamide, stereolithography materials (epoxy resins), silver, titanium, steel, wax, photopolymers and polycarbonate.

A wide range of commercial 3D printers for industrial application are now available from a range of manufactuers, the two largest of whom are 3D Systems (which works with most technologies and is rapidly acquiring many smaller manufacturers) and Stratasys (which offers FDM and polyjet matrix harware, as well as special 'drop on demand' wax 3D printers for dental work). Both of these companies had a market capitalization at the end of 2012 of over $3 billion.

Most current 3D printers are not used to create final consumer products. Rather, they are generally employed for rapid product prototyping, or to produce moulds or mould masters that will in turn allow the production of final items. Such printing of 3D objects already enables engineers to check the fit of different parts long before they commit to costly production, architects to show detailed and relatively low-cost scale models to their clients, and medical professionals or archaeologists to handle full-size, 3D copies of bones printed from 3D scan data. There are also a wide range of educational uses.

Barnatt, C. (30th November 2014). 3D Printing. Available: http://www.explainingthefuture.com/3dprinting.html. Last accessed 28th Sept 2015.

Wednesday, September 23, 2015

Research on Different types of Printers

3D Design and Modelling - Inquiry and Analyzing

In 1377, the first movable metallic types were invented in Goryeo Dynasty in Korea, which were used to print Jikjishimcheyojeol or simply Jikji, which is the oldest extant movable metal print book. The printing press was introduced to the West in the Holy Roman Empire by Johannes Gutenberg, around 1440. Gutenberg, a goldsmith by profession, devised a hand mould to create metal movable type, and adapted screw presses and other existing technologies, to create a printing system. Gutenberg's early printing process, and what tests he may have made with movable type, are not known in great detail. His later Bibles were printed in such a way as to have required large quantities of type, some estimates suggesting as many as 100,000 individual sorts. Setting each page would take, perhaps, half a day, and considering all the work in loading the press, inking the type, pulling the impressions, hanging up the sheets, distributing the type, etc., it is thought that the Gutenberg–Fust shop might have employed as many as 25 craftsmen.Gutenberg's technique of making movable type remains unclear. In the following decades, punches and copper matrices became standardized in the rapidly disseminating printing presses across Europe. Whether Gutenberg used this sophisticated technique or a somewhat primitive version has been the subject of considerable debate.

Nowadays, there are a lot of different types of printers. These are:

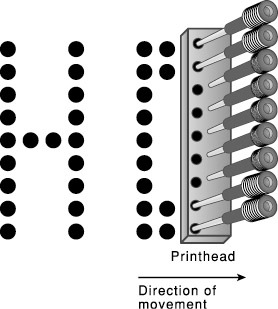

- Dot Matrix Printer is a type of printers which uses a print head that moves back-and-forth, or in an up-and-down motion, on the page and prints by impact, striking an ink-soaked cloth ribbon against the paper, much like the print mechanism.

- Daisy Wheel Printer uses interchangeable pre-formed type elements to generate high-quality output. The daisy wheel is considered to be so named because of its resemblance to the daisy flower.

- Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper, plastic, or other substrates. The emerging ink jet matereal deposition market also uses inkjet technologies, typically printheads using piezoelectric crystals, to deposit materials directly on substrates.

- Laser printing is an electrostatic digital printing process. It produces high-quality text and graphics by repeatedly passing a laser beam back and forth over a negatively charged cylindrical drum to define a differentially-charged image. The drum then selectively collects electrically charged powdered ink (toner), and transfers the image to paper, which is then heated in order to permanently fuse the text and/or imagery.

- Thermal printing (or direct thermal printing) is a digital printing process which produces a printed image by selectively heating coated thermal paper when the paper passes over the thermal print head. The coating turns black in the areas where it is heated, producing an image. Two-colour direct thermal printers can print both black and an additional colour (often red) by applying heat at two different temperatures.

Digital printing refers to methods of printing from a digital-based image directly to a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers. Digital printing has a higher cost per page than more traditional offset printing methods, but this price is usually offset by avoiding the cost of all the technical steps required to make printing plates.

Martin. (10 September 2015). Johannes Gutenberg. Available: https://en.wikipedia.org/wiki/Johannes_Gutenberg. Last accessed 28th Sept 2015.

Subscribe to:

Comments (Atom)